Solder (Soldeerder)

Information on this skill...

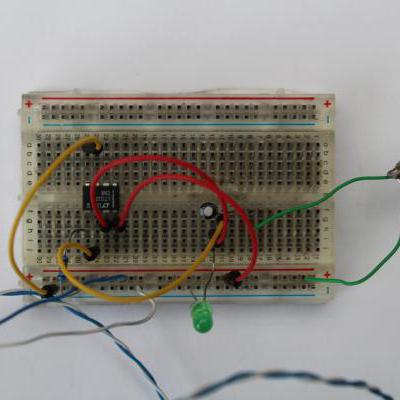

A solder solders various components together by means of a soldering iron and solder. Soldering is therefore a technique to connect metal parts with each other by means of a metal alloy. This metal alloy is called solder. An important property of soldering is that the solder will be applied with a lower melting point than the parts to be connected. In other words, during soldering it is not the intention that the various parts are attached to each other by means of fusion. When different metals merge, one speaks of welding and not of soldering. The word soldering comes from the Latin word solidare which stands for fastening. A solder therefore attaches various components to each other, such as electrical wires to a printed circuit board, creating an electrical connection. A solder works within fine electronics. A big advantage of soldering is that connections can also be easily detached when necessary. Consider, for example, replacing a printed circuit board in which various wires must be detached in order to replace the printed circuit board. When parts would be fastened by means of fusion, as is the case with welding, this is much more difficult. Soldering is generally not difficult, but requires the right actions and experience. However, there are different types of soldering such as soft soldering, brazing, induction soldering, salt bath soldering and plasma or arc soldering welding that all have different techniques and applications. The most well-known form of soldering is soft soldering. Obviously, a solder does not have to be professionally active.

A solder can therefore be regarded as a technician, who may have to deal with soldering various components. As described earlier, soft soldering is the most common in practice. Soft soldering can be applied by means of a soldering iron, which can reach a maximum of four hundred and fifty degrees. The connection of components to a printed circuit board will therefore take place by means of soft soldering. Brazing refers to materials that have a higher melting point than four hundred and fifty degrees. Brazing is also common in technology, but not to connect electronic components to each other. When brazing, you can think of plumbers, who attach copper pipes to each other by adding tin. Plumbers therefore also use soldering techniques within their work. A plumber will not use a soldering iron to solder but a burner, which can heat the materials warmer than a soldering iron.

HARD SOLDERING

Brazing can handle higher temperatures than soft soldering, and the joint is stronger. Brazing also has the advantage that the joints are easy to loosen, just as this is the case with soft soldering. In order to be soldered in a good way, it is important that the parts are clean and degreased. To achieve this, soldering water will have to be used during soldering. Soldering water degreases and ensures a good fusion, creating a good soldering. Roughening by means of sanding also ensures a better connection.

WHAT DOES A SOLDER DO

The profession of solder should also be seen as fairly general because various electrical engineers can solder for their work. In many cases, this concerns craftsmen who work within fine electronics. Learning to solder properly is important because electronic components can only function properly if the solder does not make soldering errors. Soldering errors can occur relatively easily in different ways. Think, for example, of not working cleanly or of not applying the right temperature. In addition, problems can arise due to not creating sufficient solder coverage. Especially the proper cleaning of parts is important because otherwise the solder will not adhere well. This is especially the case with old components and copper wire, which can be oxidized. The proper cleaning of components and copper wire is then important because otherwise a good soldering is practically impossible. In some cases, it is conceivable that a solder can be regarded as a cleanroom employee.

WHAT DOES A SOLDER DO:

TRAINING TO BECOME A SOLDER

As a solder, it is not necessary to follow a recognized vocational training because anyone can learn soldering. A possible targeted MBO course in which soldering will often be discussed is the MBO training first electrical engineer. This MBO course goes further than just learning to solder. There are generally enough external courses offered for people who want to learn soldering. Most courses that are offered will take a maximum of a few days. As described earlier, there are different soldering techniques, which can differ per purpose. Accounting is also important as an entrepreneur.

COMPANIES WHERE A SOLDER CAN BE EMPLOYED

A solder can work for different companies. Think, for example, of a television repair company, telephone repair company or a general fine electronics company. In addition, a solder can work for built-in companies, which have a lot to do with electronics. It is also conceivable that a solder can be regarded as an entrepreneur. As a solder, you do not have to work professionally because, for example, many hobbyists, such as model builders, can also be regarded as solders.

COMPETENCES SOLDER

The most important competence of a solder is knowing and being able to apply the right soldering techniques. In addition, the ability to concentrate and having fixed hands play an important role because it is usually fine work. In general, a solder should be able to be regarded as an all-round technician and mechanic. As a solder, you are not only responsible for soldering components. It is perfectly conceivable that a solder can also be classified as a software tester. Generally important words are insight, performance, control, precision, quality, independence and stress resistance.

LABOUR MARKET PERSPECTIVE AND CAREER OPPORTUNITIES AS A SOLDER

The labour market perspective for a solder does not really apply because the profession is too general for that. In addition, it can be a hobby solder. The career opportunities as a solder depend on the training received and cannot simply be indicated because the profession is not specific enough for this.

TERMS OF EMPLOYMENT AND SALARY SOLDER

There are no examples of the employment conditions because a solder can work for different types of companies in different industries. It is also not possible to give a salary indication because the profession is not specific enough for this.

The content on this page has been automatically translated from the Dutch language. For this reason, texts and videos on this page may contain small errors.

Lees deze informatie over Soldeerder in het Nederlands.

Mijnzzp.nl